Globally, more than 2.3 million people die each year as a result of occupational accidents or work-related diseases — that’s more than 6,300 deaths per day.

In recognition of World Day for Safety and Health at Work, which is Saturday (April 28), let’s explore some of the most common safety hazards & threats in the workplace and ways to prevent them, keeping your employees safe and in good health.

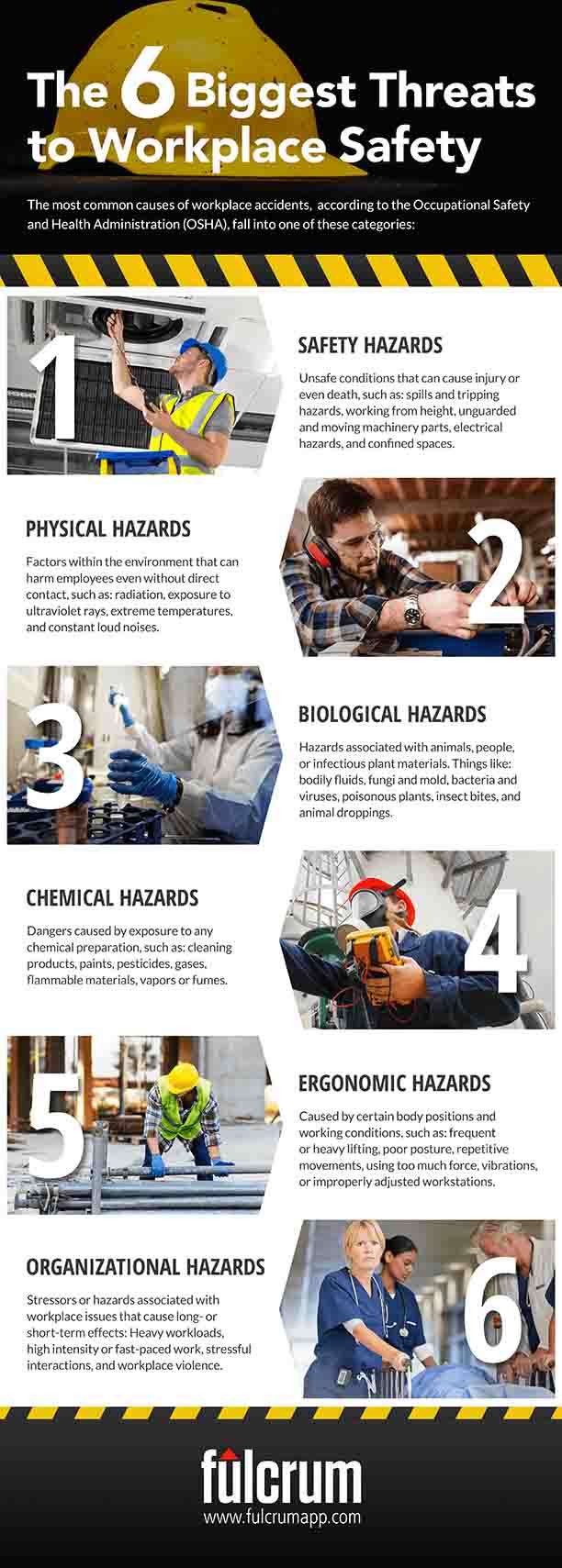

Biggest threats to workplace safety

According to the Occupational Safety and Health Administration (OSHA), the 6 most prevalent workplace safety hazards are:

1. Safety Hazards

Present in almost every workplace at one time or another, safety hazards are unsafe conditions that can cause injury or even death, such as:

- Spills and tripping hazards (e.g. electrical cords running across a floor)

- Working from height

- Machinery-related hazards (forklifts, lockout/tagout, unguarded and moving machinery parts)

- Electrical hazards (e.g. frayed cords, improper wiring)

- Confined spaces

2. Physical Hazards

Physical hazards are factors within the environment that can harm employees even without direct contact. For example:

- Radiation (e.g. electromagnetic fields, microwaves, radio waves)

- Exposure to sunlight/ultraviolet rays

- Extreme temperatures

- Constant loud noises

3. Biological Hazards

Employment inside of schools, day care facilities, hospitals, laboratories, emergency response, nursing homes, and some outdoor occupations can expose workers to biological hazards, like:

- Bodily fluids

- Fungi and mold

- Bacteria and viruses

- Poisonous plants

- Insect bites

- Animal droppings

4. Chemical Hazards

Some chemicals can be deadly, while others are simply a nuisance to workers with sensitivities, causing skin irritation or breathing problems. For example:

- Cleaning products, paints, solvents

- Pesticides

- Vapors or fumes

- Gases (e.g. acetylene, propane, carbon monoxide)

- Flammable materials (e.g. gasoline, solvents, explosive chemicals)

5. Ergonomic Hazards

Caused by certain body positions and working conditions, these can go unnoticed for days (or even years) because we don’t immediately notice them, but the effects can range from muscle soreness to serious long-term illness. Some examples of ergonomic hazards are:

- Frequent or heavy lifting

- Poor posture

- Improperly adjusted workstations and chairs

- Repetitive movements

- Using too much force

- Vibrations

6. Organizational Hazards

Causing stress and strain, work organization hazards can also go undetected for long stretches of time as they are not readily visible. They include issues such as:

- Heavy workloads

- High intensity and/or fast-paced work

- Flexibility (or lack thereof)

- Respect (or lack thereof)

- Relationships

- Workplace violence

Four tips for keeping workers safe

Guidelines and policies alone won’t ensure a safe workplace. Address safety standards from the “top-down” and keep communication open, and encourage employees to maintain situational awareness and identify potentially unsafe conditions.

Here are four ways to stay ahead of workplace hazards:

Training

It’s up to the employer to provide workers with proper training on safety protocols, including hazard recognition. This should begin upon the employee’s hire and be ongoing, with refresher courses offered regularly. It is also incumbent upon management to monitor workers to ensure they are applying protocols.

Personal protective equipment

Employers are also responsible for determining whether personal protective equipment (PPE) is necessary, providing it, and ensuring it is being used and maintained properly. Supervisors should also wear gear when appropriate, and stress to workers that wearing isn’t just a rule, but that it protects them from injury and illness.

Culture

Supervisors should model the behavior they want to see from their employees. Establish a culture in which safety is everyone’s responsibility. Stay home when sick and encourage workers to do the same, as well as to take regular breaks to fight stress and fatigue. Participate in cleanup efforts and keep emergency exits and shut-offs easily accessible to everyone.

Resources

Invest in equipment and systems that will keep your workplace safe, from training programs to mechanical aids (wheelbarrows, dollies, conveyor belts, etc.). Leverage mobile technology like Fulcrum to conduct health and safety inspections, which will enable quick identification of unsafe conditions and speed up incident reporting.

Spending a little money up front can help prevent you from having to spend a lot of money later in fines, settlements, and lost man-hours.

Companies around the world are using Fulcrum to improve workplace safety. Sign up for a free demo to get started making your workplace safer today!